Made in Italy

Focusing on the creation of a personal style, clear-cut and original, makes it possible to create a unique, characteristic and unmistakable product. Only through improvement and control of all the production steps from mechanical processes to superficial treatments, from cleaning to assembly till painting, the work of Newform is realised in the production of instruments which includes functional design concept, coupling the visual aspect of the matter with physical and real essence of sensorial well-being.

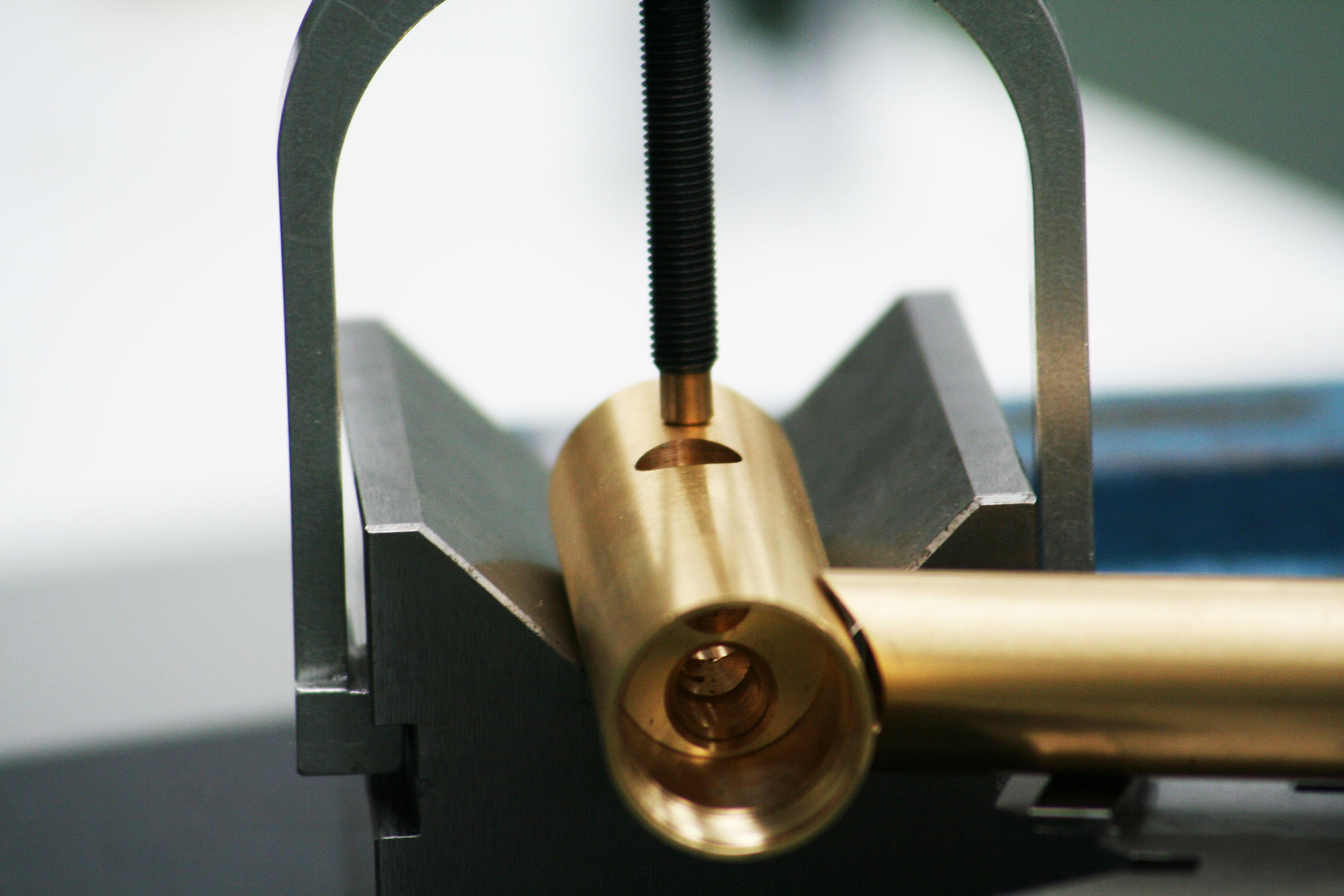

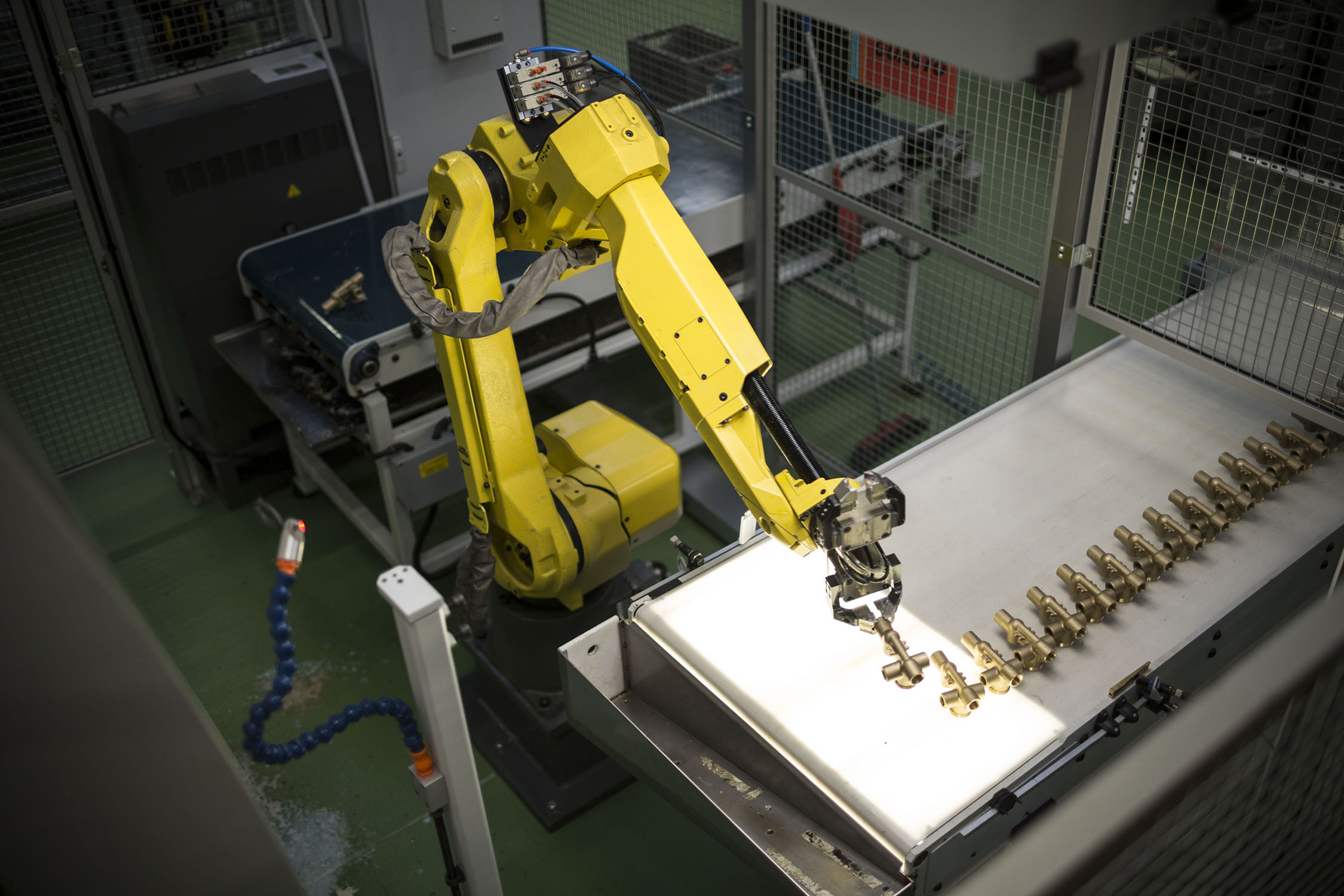

The workshop department, with the help of transfer machines, multi-spindle lathes, realizes the tap components. The mechanical processing is carried out on bars or pressed brass coming from the foundry. The processed pieces are then washed to remove impurities and material deposited on the surface. The products have to observe a polishing stage which allows making the brass surface leveled till getting it completely smooth for the next processing.

One of the two passages after the polishing is the painting. The tap components are hung on special frames, which passing through a watertight cabin are spray-painted and introduced in a furnace in order to dry the paint. Most taps are subject to galvanic electro-deposition chrome treatment.

In fact, the components of the taps are loaded on frames that, by means of an electric carriage, are immersed in the treatment basins. The first deposition is nickel, the second one is chrome, a metal that gives the characteristic hardness to the finished products, and causes the tap not to wear out.

Furthermore, there is the possibility to apply PVD and Exclusive Metal finishes to normal production and tailor-made products.

After the superficial treatments, the components can finally be assembled. At the MCI [Assembly -Test - Packaging] department, there are tables equipped for the assembly of the elements with manual equipment. Pieces are inspected by the testing units placed on board of the machine or directly at the water-testing bench.

The shipping department deals with the shipment of the product to the final customer, delivering pallets and packs to the carriers.

Newform has an intensive automatic vertical storehouse. The realization of this work allowed that all the materials present in the company could be put in one place. Material handling occurs by means of computerized shuttles that carry the necessary to all the production units.